Everything You Need to Know About

Impact-Resistant Gloves

Impact-Resistant Gloves

Knocks, bumps, and pinches can rationalization a range of hand injuries from bruises to wrenched bones.

Like most hand injuries, these impact injuries can be reduced and prevented. But, with the unbridled selection of safety gloves on the market, how do you segregate the weightier protection for your workers?

Everything Well-nigh Impact-Resistant Gloves

Everything Well-nigh Impact-Resistant Gloves

Forces At Work In An Impact-Resistant Glove

Transfer of gravity from an object to your hand.

We know impact like knocks, bumps, and pinches rationalization impact injuries like bruising and wrenched bones, but what exactly causes an impact injury?

When an object strikes or pinches a hand, gravity is transferred from the object to the hand. The power of this gravity is what causes a shift or ostracism of skin, bones, and muscles that leads to injuries such as lacerations, wreck breaking, and bruises.

How Impact-Resistant Materials Work To Prevent And Reduce Injuries

To reduce or prevent impact injuries, the key is to increase the time over which the impact occurs. This way, the hand does not swizzle all the impact at once. Instead the gravity of the impact is spread over time, lessening the severity of the impact. In other words, you’re trying to minimize the peak gravity that your hand experiences.

The primary way to unzip this is through:

Deformation

Deformation is the worthiness of impact-resistant material to slow the impact gravity transferred into the hands. It does this by deforming, or waffly shape temporarily, to slow the gravity and lessen its impact on the hands.

Deformation is achieved using impact-resistant back-of-hand materials (also known as bumpers), which are tying to the glove shell.

Ultimately, the goal of the bumpers is to optimize deformation, so the impact gravity is slowed as much as possible.

A simpler way to understand deformation is to imagine landing on a firm mattress versus a touchable floor from a significant distance. As you hit the mattress, it stretches when you land and bounces you a couple of times surpassing your soul finally comes to a stop. Now if you land on a touchable floor from the same height, you come to an firsthand stop all at once. But in this case, you transfer an incredible value of gravity into your body, sustaining increasingly severe injury. The result in both instances is the same. You come to a stop! But, in the specimen of landing on a mattress, impact gravity is transferred much increasingly slowly, decreasing the likelihood and severity of injury.

This is exactly how we think well-nigh manufacturing impact-resistant safety gloves.

Everything Well-nigh Impact-Resistant Gloves

Everything Well-nigh Impact-Resistant Gloves

How We’ve Engineered Our Impact-Resistant Gloves

Impact-resistant bumpers form a rigid rubber padding that covers the when of hand, knuckles, and fingers as shown.

There are three components to how we innovate bumpers to unzip the weightier impact protection for workers:

Material

Design

Placement

Impact-Resistant Bumper Material

As discussed earlier, to unzip constructive protection from impact hazards, materials used for the bumper must be optimized for deformation to reduce the impact undivided by the hands. One of the most worldwide impact-resistant materials used to unzip this is TPR (Thermoplastic rubber).

TPR is one of the most worldwide materials used to unzip impact protection and performs well at a relatively low thickness. It has shock-absorbing properties and offers upper tautness for bending, stretching, and moving. All this helps maintain range of motion for workers to work comfortably while moreover providing impact protection. TPR moreover performs well in unprepossessed and hot environments.

Impact-Resistant Bumper Design and Placement

At Superior Glove, we leverage technology to maximize impact protection vastitude the inherent characteristics of a single material. To do this, we engineer material blends and incorporate innovative designs and bumper placement that improves our gloves’ performance under impact while maintaining as much repletion and dexterity as possible.

Our 4Pro Goatskin Driver gloves, using our proprietary blend, offer the industry’s highest level of impact protection (ANSI Level 3 impact resistance) without increasing bumper thickness.

Our TenActiv STXFNVB uses patent-pending skeleton bumpers to indulge upper dexterity while providing maximum ANSI Level 3 impact resistance.

STXFNVB uses patent-pending skeleton bumpers to indulge upper dexterity while providing maximum ANSI Level 3 impact resistance.

Everything Well-nigh Impact-Resistant Gloves

Everything Well-nigh Impact-Resistant Gloves

You know your workers squatter impact hazards, but how do you decide which level of impact protection to buy?

To help you decide, industry standards were established with specific testing methods to assign protection levels for safety gloves, including impact resistance.

These standards were introduced to create a worldwide language for safety managers, distributors, and manufactures to pinpoint protection levels and substantiate protection claims.

Note: There are no differences in the testing methods and ranking levels for the EU and the UK Standards.

However, PPE (and other goods) sold in the UK are now mandated to have UKCA marking (UK Conformity Assessed) instead of CE marking (Conformitè Europëenne-European Conformity) which are used for PPE (and other goods) sold in EU countries.

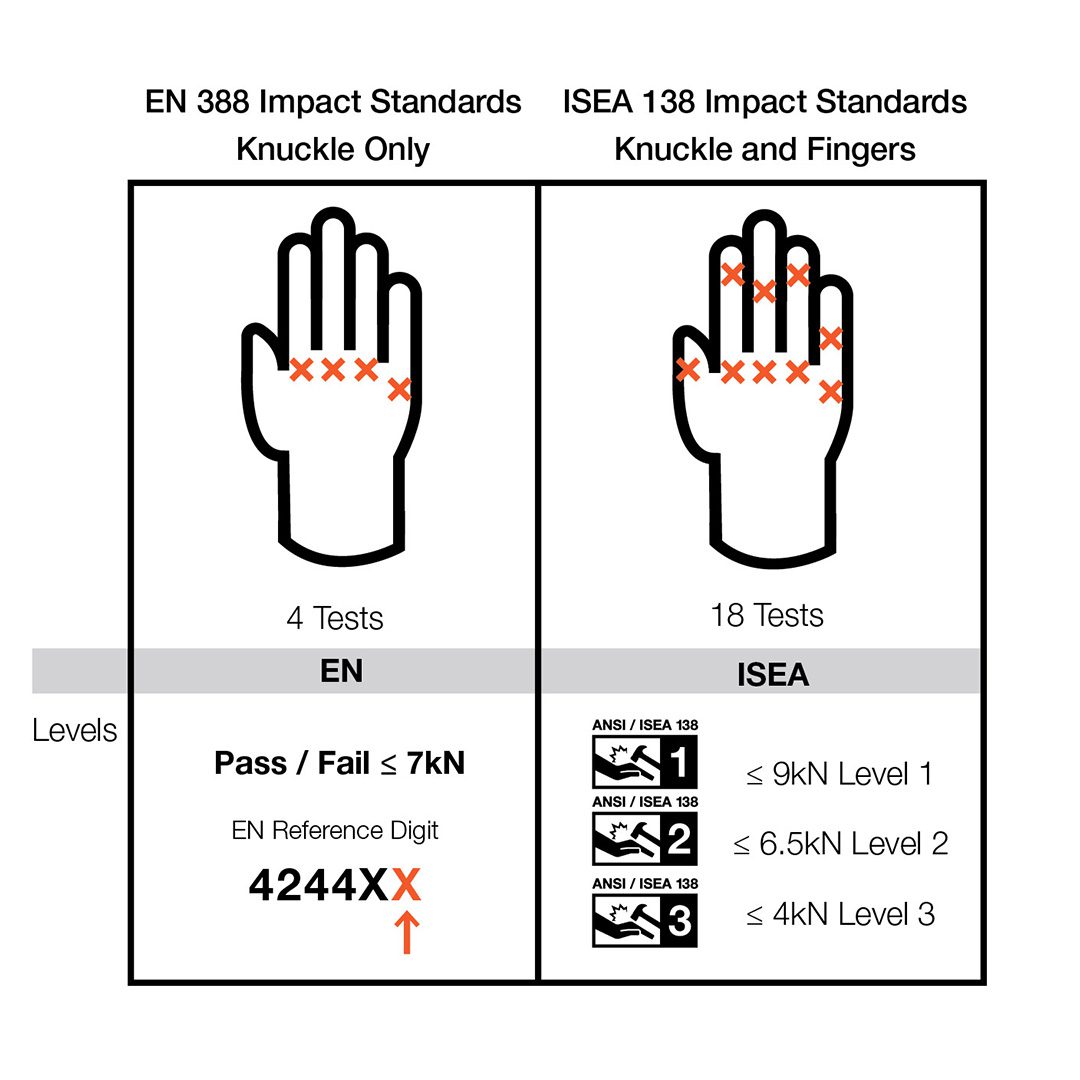

There are three industry standards governing impact protection:

North American Standard (ANSI/ISEA 105)

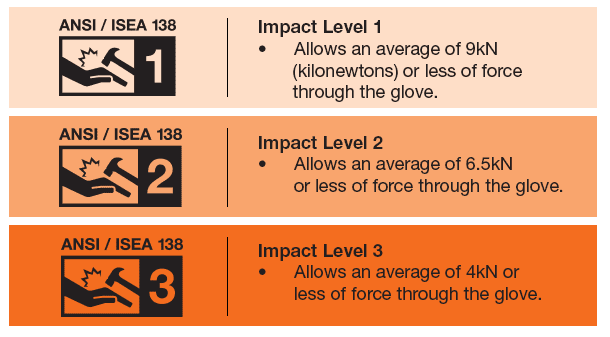

The ANSI/ISEA 138-2019 standard established the minimum performance, classification, and labeling requirements for gloves designed to protect the knuckles and fingers/thumb from impact. Three performance levels are used to classify impact resistance: level 1, 2, and 3, with level 3 offering the highest level of protection.

When looking for impact protection on gloves, the ANSI Impact level is represented by the pursuit icon:

What this substantially ways is that the higher the glove rating, the largest the protection.

Testing Method:

The palm of the impact-resistant glove is cut away, so the testing zone only includes the when of the glove’s shell and the impact titillating material. This halved glove is then placed on a metal anvil with a special gravity transducer underneath to record how much gravity goes through the glove. Next, a 2.5 kg striker is dropped on the testing location, imparting 5 joules of energy into the glove. The gravity transducer records the impact force. This test is repeated for each knuckle, finger, and thumb (knuckles are test four times while fingers and thumbs are tested five times). The stereotype of the knuckle tests is compared to the stereotype of the fingers/thumb tests to determine the final impact testing score.

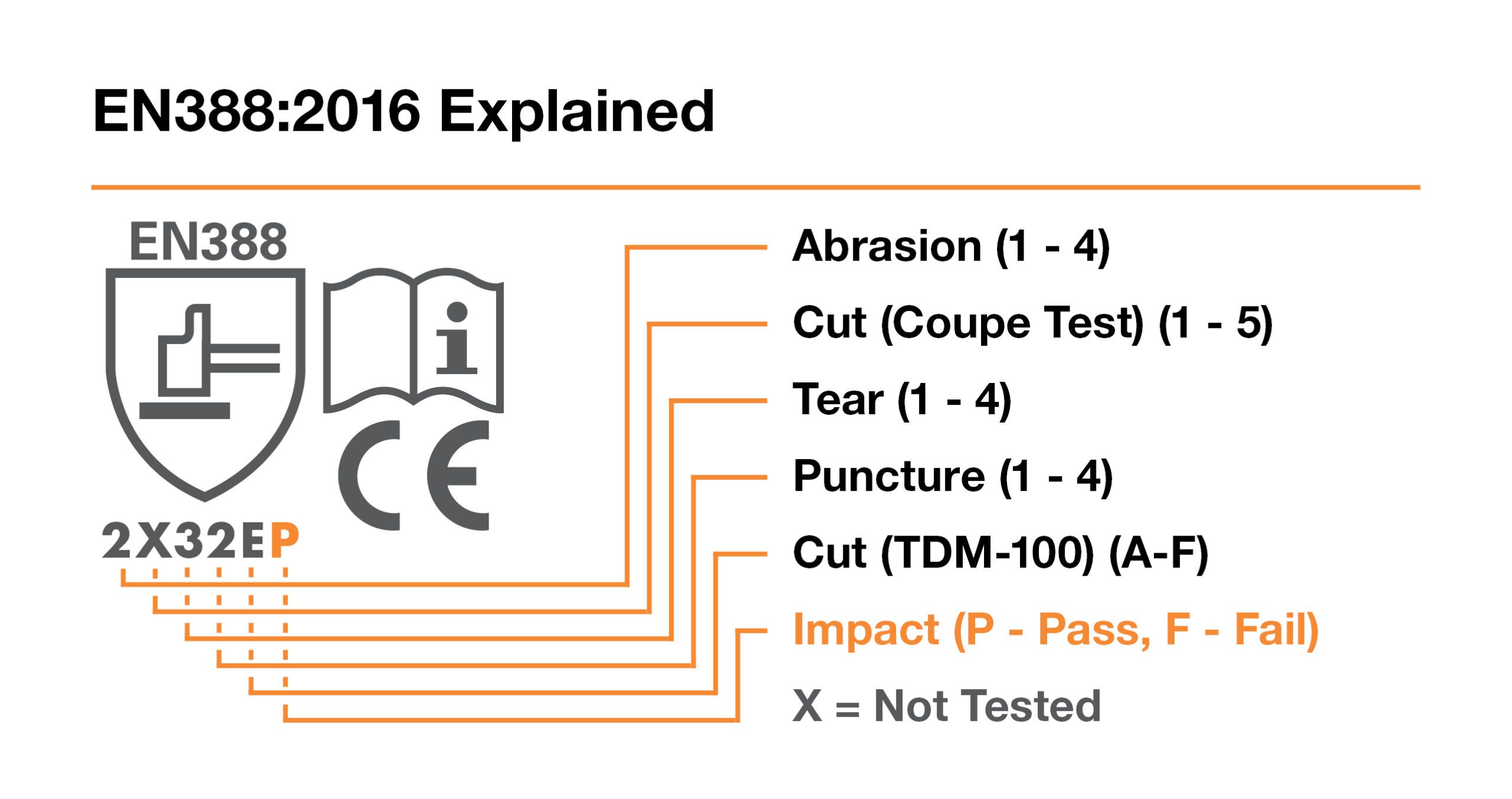

EN388: 2016 European Standard

Compared to the ANSI/ISEA 138-2019 standard, the EN388 dictates fairly limited testing criteria for impact protection. Under this standard, the same testing method is used as ANSI/ISEA, but only the back-of-hand material on the knuckles is tested, not the fingers or thumb. Under this method:

- If the stereotype transmitted gravity is less than or equal to 7kN, then the gloves receive a pass rating, indicated by the letter “P” on the EN388standard shield

- If the stereotype transmitted gravity is higher than 9kN, then the gloves receive a fall rating, indicated by the letter “F” on the EN 388 standard shield

- A letter “X” indicates that a glove has not been tested

An example of the impact-resistant markings can be seen in the image below:

UK Conformity Assessed (UKCA) Standard

There are no differences in the testing methods and ranking levels between the European Union and United Kingdom standards. however, PPE sold in the UK is mandated to have an icon (as shown) to certify they conform with UKCA (UK Conformity Assessed)

In wing to the impact-specific consideration that we’ve discussed above, there are other factors to consider when choosing impact-resistant gloves to ensure wearability, cost-effectiveness, comfort, and other factors that determine successful adoption.

For this reason, we’ve created a comprehensive guide that takes a closer squint at the torso of safety gloves in our Glove 101. Our guide expands on each glove component and its function, including glove materials, patterns, gauges, coating, linings, gloves by hazards, sizing, care, laundering, and more.

The post Everything You Need to Know Well-nigh Impact-Resistant Gloves appeared first on Superior Glove.